Too much of what is produced on our planet is made from non-renewable materials. No material can be reused or recycled forever as losses and degradation will always take place and virgin material will be needed in the loops. In the case of paper, the raw material is renewable and supplied to the loops in line with the principles of a circular economy. Through sustainable forestry practices the tissue paper industry regrows and regenerates its raw material and provides a sustainable resource. Trees are positively beneficial for our planet. They capture and store billons of tonnes of carbon dioxide while at the same time providing the earth with much needed oxygen. They emit particularly large quantities of oxygen during the growing phase, hence underlining the importance of continually replanting trees. Trees play a crucial role in the earth’s eco-system and paper boasts first-class environmental credentials: It is natural, biodegradable, and comes from a renewable resource.

COMMITTED TO SUSTAINABILITY ACROSS THE SUPPLY CHAIN

ETS is committed to driving sustainable practices throughout the industry. It is also looking to increase sustainability across the supply chain – from water and energy through to transport and recovery. Tissue paper production also ensures that every part of the raw material – trees – is put to good use. It uses mainly bark and twigs from the lumber industry which are made into pulp that is the basis of tissue paper.

SUPPORTING CERTIFICATION SCHEMES

Third-party certification is one of the best ways to ensure that suppliers meet recognised standards. It lends credibility to the sector and offers reassurance to both customers and consumers. Most tissue producers support the different international and national forest certification schemes and over 80% of the forests owned by paper and lumber companies in Europe are certified. Some tissue producers have chosen to carry labels on their products in order to show their high environmental credentials – such as the EU Ecolabel, the FSC and PEFC labels and regional labels including Nordic Swan and Blue Angel. The paper sector is also signatory to the Legal Logging Code of Conduct which condemns illegal logging. The EU timber regulation furthermore upholds industry standards and ensures that only products from legally sourced wood are sold within the EU. Some 11% of timber felled in the world is used to make paper, and 83% of Europe’s paper mills are certified by an environmental management system.

TISSUE PAPER IS

NATURAL

AND MADE FROM A

SUSTAINABLE RESOURCE.

SUSTAINABILITY

HAS BEEN

A WAY OF LIFE

FOR THE TISSUE INDUSTRY

FOR GENERATIONS.

IT HAS ALWAYS HAD TO

THINK LONG TERM

AS ITS RAW MATERIAL

TAKES MANY DECADES

TO GROW

SUPPORTING THE EU AND UN GOALS

Tissue paper producers are active supporters of the EU Circular Economy Action Plan – a key building block of the European Green Deal, which has a number of sustainability targets including transforming the EU into a modern and competitive economy. The goal of the Action Plan is sustainable growth and it lays special focus on resource efficiency with more waste prevention, reuse and recycling and the phasing out of wasteful practices like landfill. This goal of enabling sustainable consumption and production is also reflected in the United Nations Sustainable Development Goal 12: Responsible consumption and production. Tissue products have an important role to play here. They are essential for people’s health and hygiene. While paper is the most recycled material in Europe, with recycling rates of over 70%, tissue paper, because of its applications in toilet paper, tissues etc, is usually a single-use product which typically goes to waste after use. Tissue products nevertheless fit neatly into existing waste management schemes and can in many cases provide a benefit such as incineration with energy recovery or composting.

DRIVING CIRCULARITY UP AND DOWN THE VALUE CHAIN

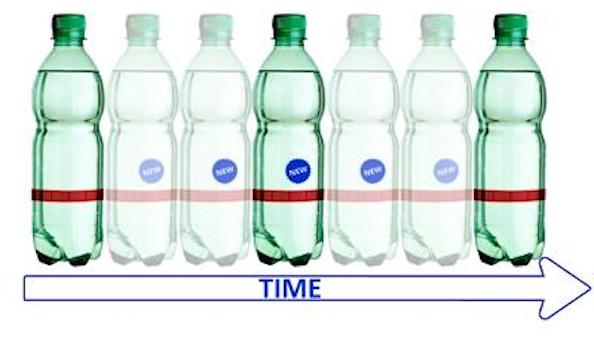

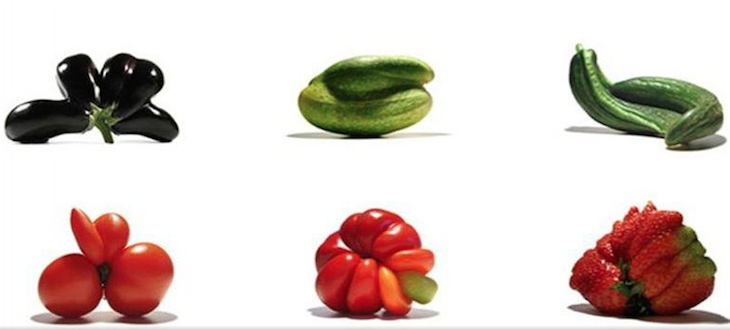

Many tissue paper producers are supporting the development of new, circular business models using innovation to create closed-loop products and processes. This will serve to increase product recovery and minimise waste. There is a focus on reducing greenhouse gas emissions, transferring to renewable energy and decreasing water use. Some 58% of the Europe’s pulp and paper industry’s energy consumption already comes from renewable biomass, and it is proud to be the largest single user and producer of bio-energy in Europe. The sector also continues to work on reducing its impact on water consumption and is an active partner in the development of water stewardship. Paper making machines have reduced water consumption by 30% over the past 10 years as a result of more efficient water circulation (Kemira), and the amount of water needed to produce one ton of pulp has fallen five-fold since 1970. Many individual producers are promoting zero waste to landfill, eliminating waste, reducing packaging weight and fostering recyclable packaging and the use of recycled content. They are also exploring innovation in product design and development. In the area of ‘reduce’, the industry is seeing the emergence of new products that use less material for the same functionality. It is also witnessing new sustainable products that use fresh, wood-based fibre, recycled fibres and alternative fibres. It is important to promote circularity in this regard in order to increase the availability of paper for recycling as a secondary raw material. Recycling plays an important role in the sustainability of the paper cycle. Paper recycling rates rise every year and currently stand at 71% in Europe (https://www.paperforrecycling.eu/). Tissue paper producers are working together with their packaging suppliers to turn waste into a resource through collection, sorting and recycling.

PLACING THE CUSTOMER AT THE CENTER

Key to driving a more sustainable and circular tissue paper industry is placing customers at the centre and ensuring that they are kept informed. Many tissue paper producers provide easy-to-understand information about sustainable production and consumption, proper waste disposal and anti-littering. It is provided to both consumers and professional customers to keep them up-to-speed and encourage them to play their part in driving circularity. Sustainability is often described as having three pillars – environmental, economic and societal. Tissue paper products play an essential role here too. Tissue is a material that makes our world better. Tissue products are essential for people’s health and hygiene and reduce the risk of infection while upholding cleanliness.

Tissue paper product from toilet tissue and handkerchiefs to paper towels and kitchen roll will continue to offer a sustainable, hygienic and practical solution both inside and outside the home in the years to come.